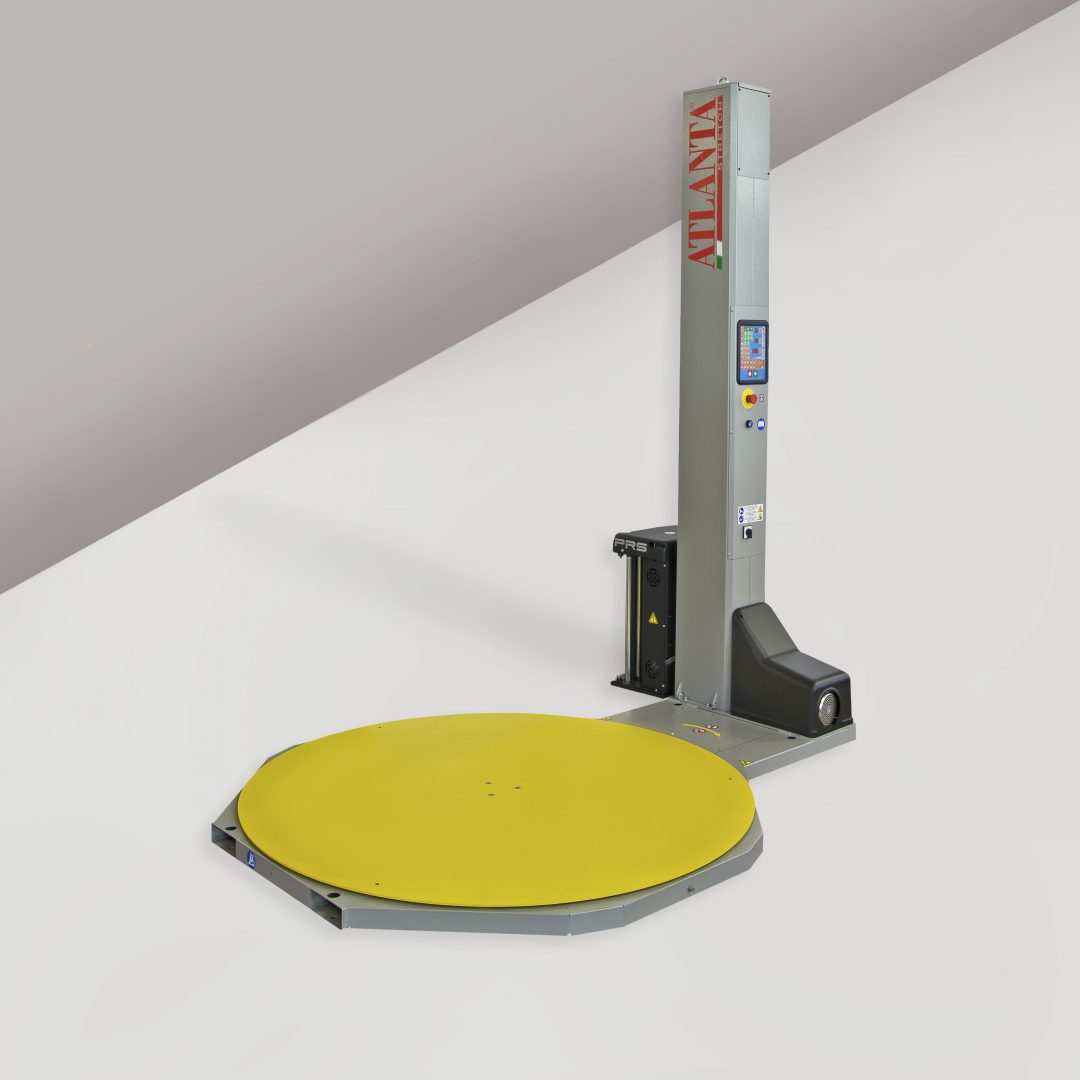

We installed 4 new high performance Atlanta pallet wrappers, reducing the weight of plastic used to wrap each pallet by 12.4% - whilst also improving load stability and safety

Introduced Extremus pre-stretched hand pallet wrap and dispenser, reducing the weight of plastic used to wrap each pallet by an average of 40% - whilst removing the need for operates to walk backwards